Related Products

Browse History

Aircooled laser welding machine

The best model to replace:

Maxphotonics MA1-65 / MAX X1W-1500

IPG LightWELD 1500

Operation of the machines

Torch demo

Key specifcaiton

|

1 |

Model |

1200W |

1500W |

|

|

2 |

Interface Type |

QBH |

QBH |

|

|

3 |

Power |

1200W |

1500W |

|

|

4 |

Laser Wavelength |

1064-1080nm |

||

|

5 |

Power Adjustment Range |

10%-100% (Gradually Adjustable) |

||

|

6 |

Fiber Length |

10m (Customerizable) |

||

|

7 |

Cooling Method |

Air Cooling |

||

|

8 |

Continuous Operation |

24h |

||

|

9 |

Operating Temperature Range |

0-40°C |

||

|

10 |

Humidity Requirement |

<70% Non-condensing |

||

|

11 |

Power Supply |

Single-phase 220V±10%, 50/60Hz AC |

||

|

12 |

Weld Seam Requirement |

≤0.05mm (Welding range expandable to 1mm gap width with wire feeder) |

<0.3mm |

|

|

13 |

Overall Dimensions |

LWH: 730mm350mm640mm (Including Wheels) |

||

|

14 |

Total Weight |

43KGS |

67KGS |

|

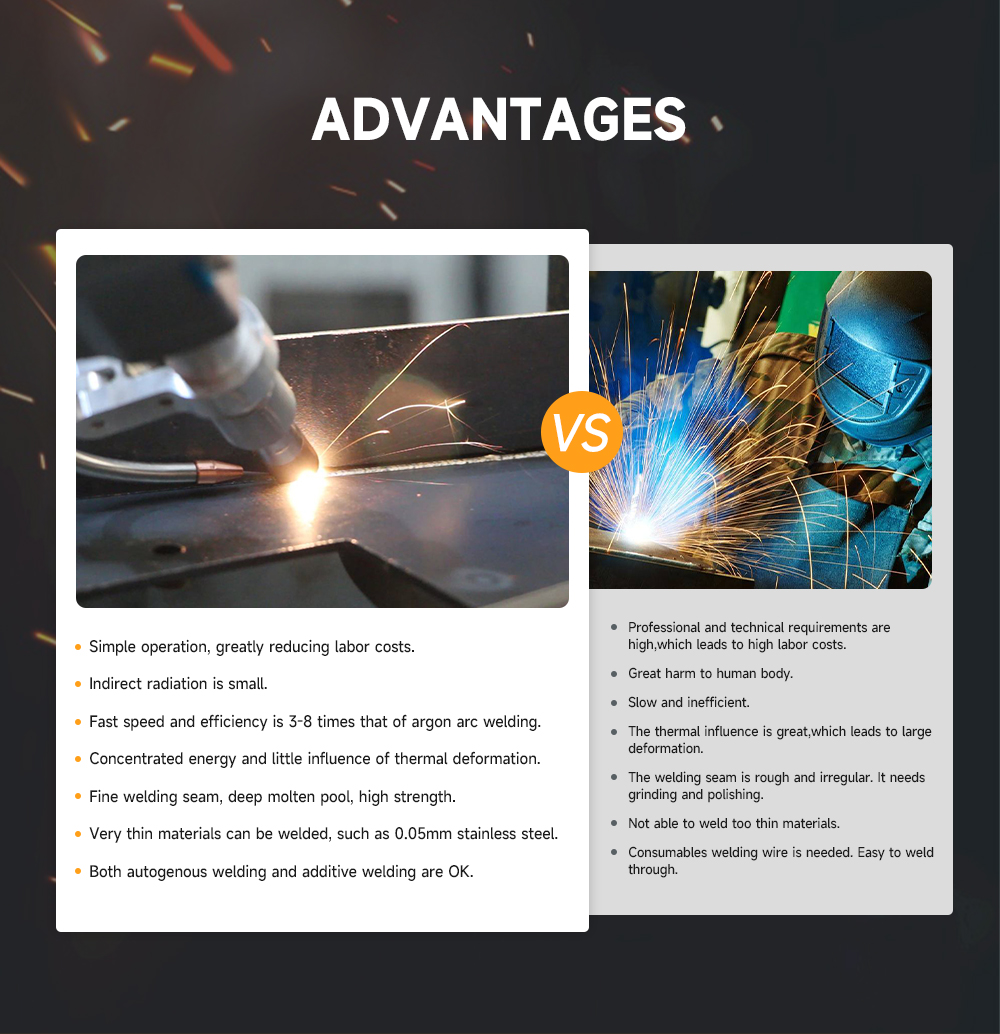

Key Features

● New generation technology, smaller size, lighter weight, more flexible mobile welding

● 3in1 gun for welding/cutting/cleaning/post weld cleaning

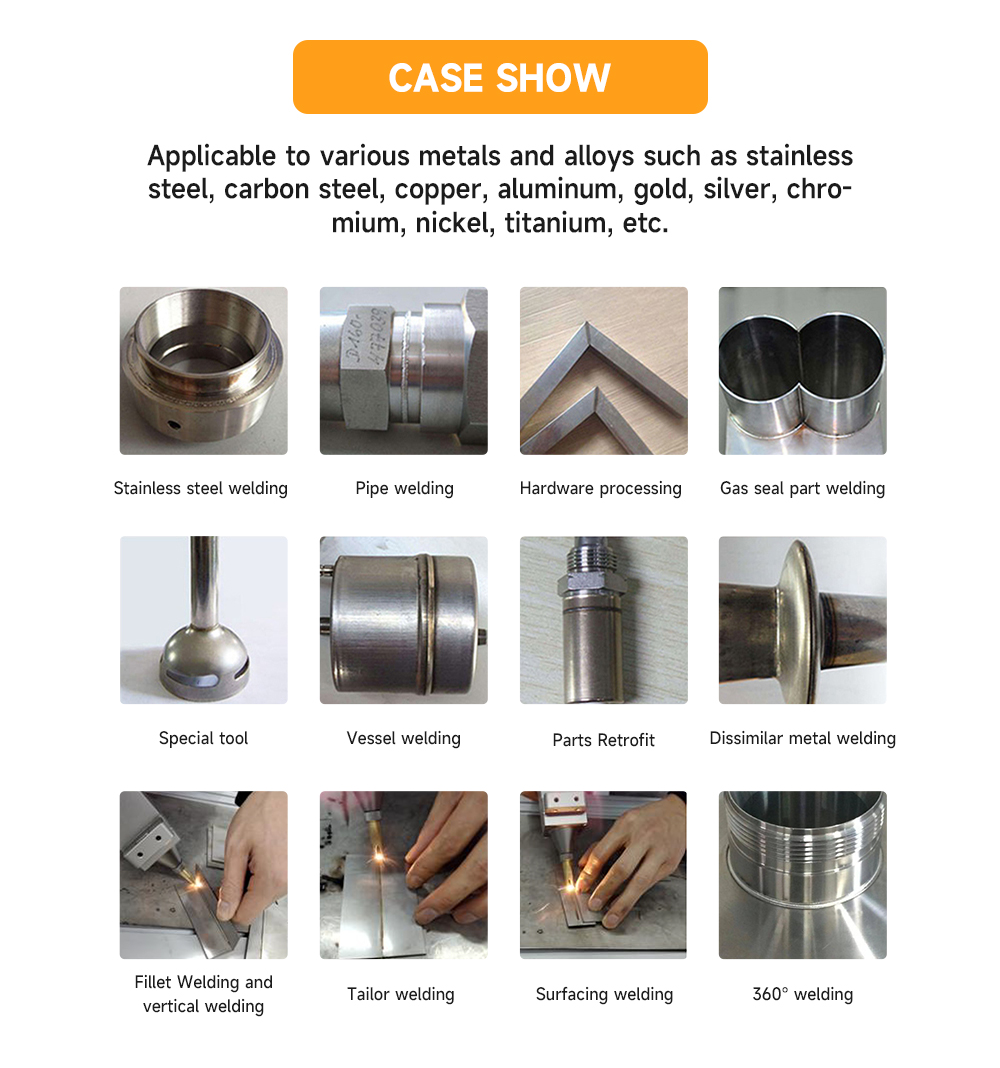

● Simple operation, beautiful welding seam, fast welding speed, and no consumables. It can perfectly replace traditional argon arc welding and electric welding for welding thin stainless steel plates, iron plates, galvanized plates and other metal materials.

● Advanced operators can customize presets, save for future use and can be used by novice operators to produce the same results.

● Ultra-low operating cost, the laser consumes only 1 to 1.5 degrees per hour; it can weld various thin metal plates;

● The system can be switched to different language:English, Chinese, French, Spanish, German, Arabic, Russian, Polish

● CE certificate.

What's included?

Package 1 (include with the power source + laser gun SUP21T + earth clamp & cables)

Dimension of the wooden box: 70*75*84cm(L*W*H)

Gross weight: 50kgs

Package 2 (inlcude with the auto wire feeder SUP-AMF-A-Z5)

Dimension of the carton box: 62mm*32.5mm*46mm(L*W*H)

Gross weight: 18kgs

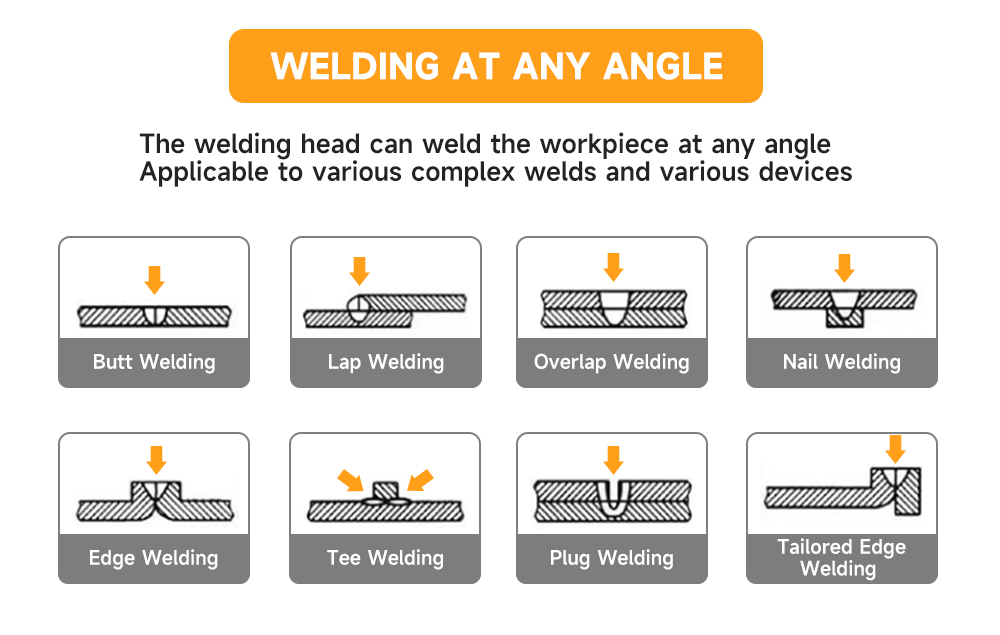

Q1: I want to weld stainless steel and mild steel, how to choose which laser power suitable for me?

Following are the welding parameters for your reference, please have a look.

|

Machine model

|

Butt welding maximum thickness

|

90° vetical welding maximum thickness

|

|

|

||

|

1500W handheld laser welder

|

Stainless steel: 3mm

Galvanized sheet: 2mm Iron: 3mm Mild steel: 2mm Aluminum: 2mm Brass: 1mm |

Stainless steel: 3mm

Galvanized sheet: 2mm Iron: 3mm Mild steel: 2mm Aluminum: 2mm Brass: 1mm |

A2: Usually Argon gas and Nitrogen gas used as a shielding gas. It is used to protect the welding part from turning black. Use the shielding gas can make the welding part with nice welding effect, no need to do further polishing process again.

Q3: What material would i use Argon and which material would i use Nitrogen?

A3: Actually both Nitrogen and Argon can used for all materials. Like: Stainless steel, mild steel, carbon steel, iron, aluminium, brass, etc. You can choose to use Nitrogen or Argon as shielding gas according to your market price.