Browse History

Specifications

1.2 CHARACTERISTICS OF SYSTEM

1. 7 inches 800*680 dots color LCD.

Man-Machine-Dialog software and Professional Hot Key design for easy cutting operation, user-friendly as Hypertherm’s EDGE controller.

2. Multi-language file system and menu, and the menu can be switched only by one key.

3 DSP core can control the machine move in high speed accurately, stably and in low noise.

4 Long-distance remote control can control the machine to move forward ,backward, left, right and cutting start, stop and so on (optional configuration).

5 Support the EIA code (G code) and various nesting softwares

6) compact keyboard design and easy to input files.

7 Operations such as Proportion Zoom, Rotate, Mirror, Array display, Steel plate angle adjust…..all available and have professional solution in the CNC controller.

8 Coordinate system can be customized to support the two-dimensional coordinates of all eight kinds.

9 All input and output port type and the number can be customized (normally open or normally closed)

10) System Self-diagnosis for easy trouble-shooting.

11) all functions and techniques can upgrade online

12 Import and export files by single or all files.

13) Support the Flame, Plasma, Dusting draw and Demonstration four kinds of mode.

14) Flame and Plasma are separated in the control IO ports.

15) Support THC, two level preheat, three level pierce in flame mode.

16) Plasma arc feedback, positioning feedback, automatically shut down the arc at the corner.

17) Support edge cutting. It can save the preheat time for the thick steel plate.

18 Movement speed can be real-time acceleration, deceleration.

19 According to plate thickness, the cutting speed is automatically restricted by a speed limit in the corner, effectively preventing over burn.

20 Dynamic/static illustration of the process, graphics zoom in / out, dynamically tracking cut-off point under zooming state.

21 Automatically memorize the working situation and the last cutting point when power off.

22 "Cutting offset" function can avoid waste the steel plate when the nesting of the plate is calculated wrong.

23 set up different administration authority and the corresponding password to safeguard the interests of managers.

XPTHC-4H supports almost all plasma cutters on market like Hypertherm, Thermal Dynamics…

And it supports all CNC cutting controllers on market like Hypertherm, Burny industrial level controllers or Mach3 such DIY controllers, because XPTHC-4H can start Auto Height control with or without Auto enable signal from CNC. But with Auto enable/disable signal from CNC, THC would work better.

Basic Parameter and Feature

Input Power:AC24V+10%,50Hz/60Hz or DC24V±20%;

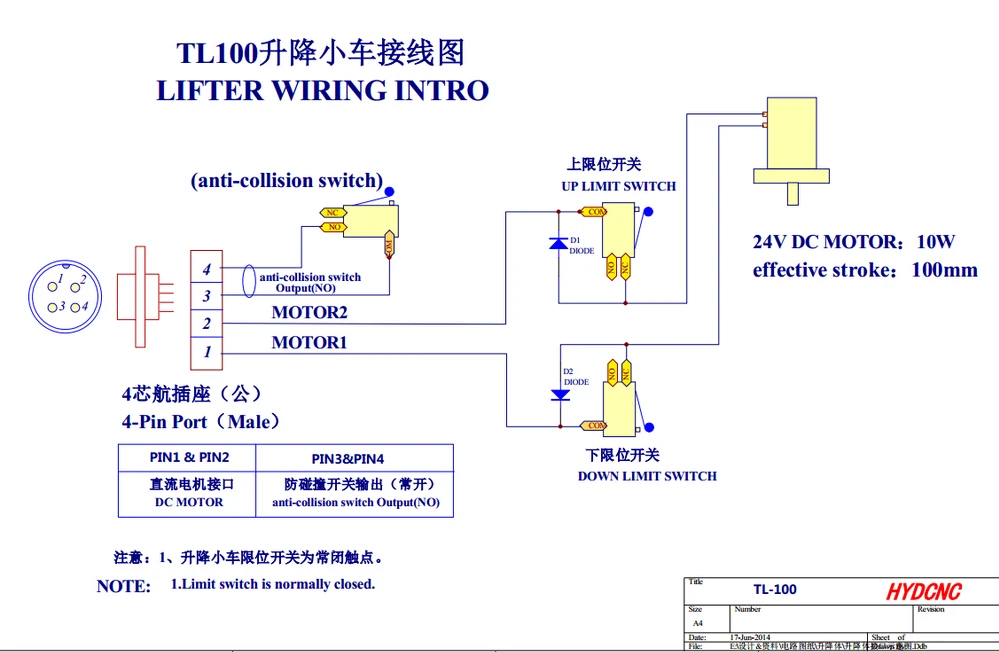

Motor:DC24V DC motor;

Motor Drive:PWM;

Output current:0.1A-1.8A;

Load capacity:Max 20W;

Working temperature:-10∽60℃;

IHS:Switch IHS & Proximity switch IHS; Do Not support the retaining cap HIS

Work way: check the arc enable output, 200mA optical coupler OC door output

Voltage Divider ratio: 50:1 non-isolation on voltage divider; 1:1 isolation inside of THC

Control accuracy :±1V∽±3V,depends on the motor and lifter of user.

The speed of lifting:1000mm/min ∽ 3000mm/min(Contact the supplier if it exceeds the range of speed);

Arc Voltage rang:50V∽250V,

Over protection:PWM adjusting, current feedback;

Max speed test:12000mm/min( it’s related to the setting on the lifter’s speed and motor’s start voltage and sensitivity)

XPTHC-4H is the newest design THC, special for portable CNC cutting machine and small bench type machine, with 32 ARM processors, and analogous circuit height control together.

Feature:

1, installation: user could install the THC’s operation panel on the work interface, or install it at the convenient operation place. Install the main body at a suitable station.

2, height controller: could change the auto cutting height at any time

3, two modes of the setting arc volt:

A, Setting arc volt mode: set the setting arc volt on the operation panel, let the THC work on the setting arc volt status. It’s the traditional work way.

B, sampling arc volt is the setting arc volt: when the THC control the torch finish the HIS and plasma start, and CNC controller open the AUTO signal to THC, and THC will test the arc value as the setting arc when at beginning the AUTO status. It’s suitable for some small plasma.

4, High Sensitivity: adjusting the THC’s sensitivity, could realize the arc volt change 1V, the arc voltage output will change 1.5V~4V, and don’t occur the vibration. So the lifter’s start voltage is closed related to the THC’s sensitivity, Our lifter’s start voltage is 1.5V ~2V.

6, Good stable: XPTHC-4H has 5 sets isolation power inside, to realize the I/O isolation; sampling arc volt isolation; drive isolation; and control isolation.

XPTHC-4H is with full functions of the Stand alone Arc Voltage Torch Height Controller. But as it’s with small body, the motor of the lifter should be less than 20W on the portable CNC cutting machine, light gantry machine and small bench type machine etc.

Picture Show

Lifter Features:

1. DC24V motor, 130mm stroke, 1500mm/min for plasma, 900mm/min for flame cutting, enough for table type , portable type, light gantry cutting machine

2. With mechanical anti-collision design inside lifter, and this function can be used for arc voltage THC's initial height sense ( IHS), with this type of IHS, it can protect THC effectively from HF plasma's interference.

Because it doesnt need to connect IHS cable from torch tip, avoid high voltage on plasma start.

3. We also have big lifter with best design for high precision cutting, and we can supply lifter with THC, CNC together for customer's convenience.

We can offer you professional technical support for all THC, CNC, Lifter. secure you trouble free!!!!

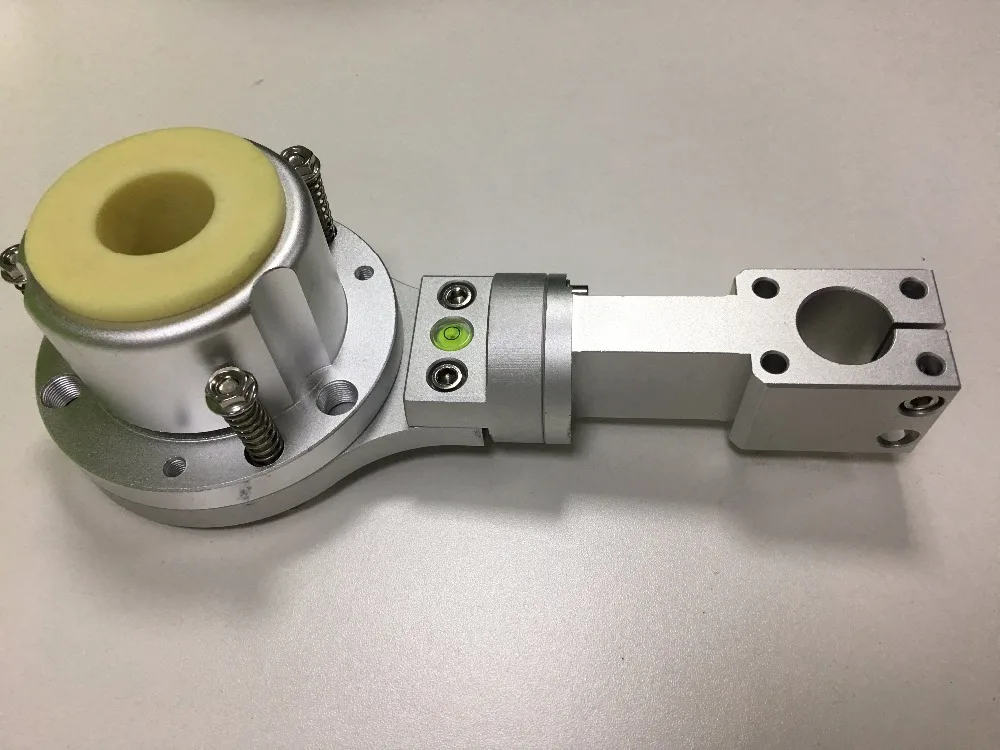

Anti-collision fixture :Integrate the IHS and anti-collision function together.

There is proximity switch connected with THC, for IHS; and optional proximity switch connected with CNC.

It is supplied with our plasma THC, offer proximity switch IHS to backup torch retaining cap IHS.

Also it can be used as torch holder with anti-collision function.