> Welding Tools&Accessories > Welding&Cutting Repairing > CNC Parts > THC(Torch Height Controller) > BT005332Browse History

Plasma Torch height controller/plasma arc voltage height controller

Arc voltage height control CNC plasma cutting machine parts to increase AVC118

Introduction

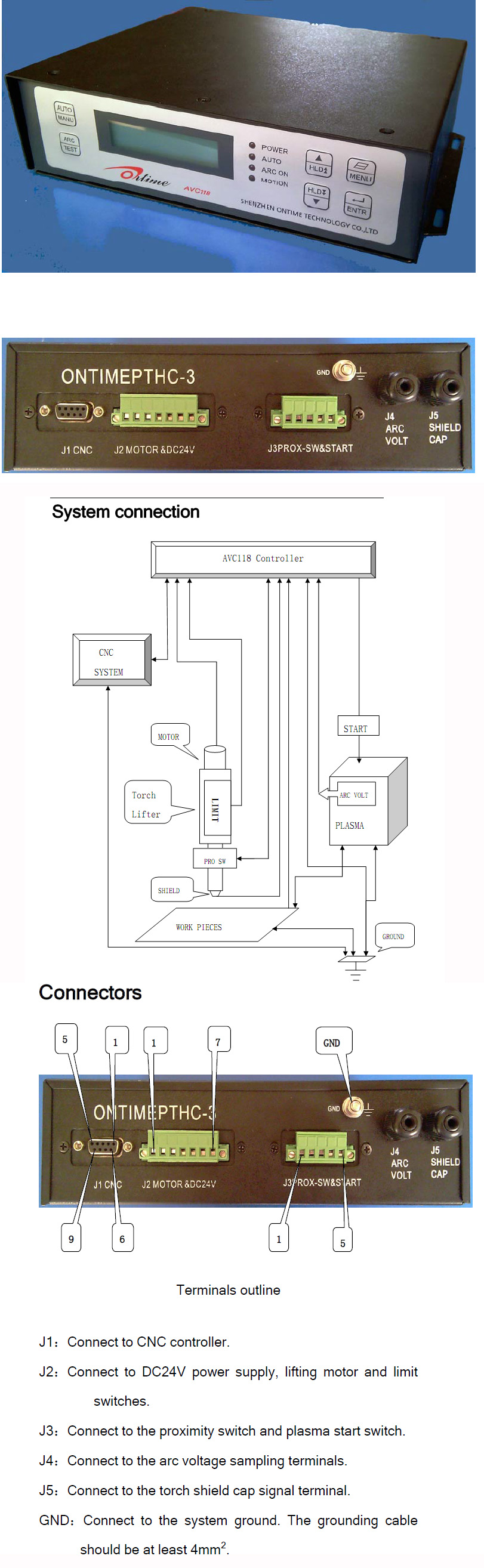

The AVC-118 is a voltage sensing torch height control system

that is designed for the CNC plasma cutting machines.

During cutting process, the cutting current always keep constant, and the cutting arc voltage will be changed with the height of torch. When the distance between the torch nozzle and work piece increases, the arc voltage increases, on the opposite, the arc voltage will decrease. AVC118 plasma arc voltage torch height controller will detect the voltage changes, then control the distance between cutting torch and work piece via the lifting motor in order to keep the arc voltage within a given range, so that the height of cutting torch is Specifications Work power: DC24V±10%, 3-5A. The total power of the DC supply must be 10W bigger than the power of the torch lifting motor. Lifting motor: DC24V motor within the power of 60W. Drive Mode: PWM (pulse width modulation) Working Temperature: -10℃ - 60℃ IHS (Initial Height Setup) mode: Inductive proximity switch mode. Torch tip ohmic contact mode, only be suited for the plasma power which has less HF and HV interferences and working in dry cutting condition. Arc voltage divider ratio: 1:100. Accuracy: ±1V to ±5V adjustable. Outline: 240mm/210mm/60mm(L/W/H) Operation mode The AVC118 will work in auto mode after power on. This means that the controller will take the responsibility to monitor the arc voltage and modify the torch height correctly during plasma cut. In case of needed, you can Press the AUTO/MANU key to enter into manual operation mode, and it is your responsibility to maintain the torch height correctly.