Categorie

- Toys

- TIG Pen

- Welding Gauge

- Magnetic Welding Holder

- Electrode Holder

- Welding Trolley

- Air Gouging Torch

- Earth Clamp

- Chipping Hammers

- Gas Hose

- Wire Brush

- Clamping tools

- Welding Cable

- Welding Cable Connector

- Input&Output Terminal

- Aviation Plug Panasonic Type

- Welding Anti-Spatter Gel/Spray

- Infrared Thermometers

- Tunsten Carbide Rotary Burrs

- Abrasive Discs

- Welding&Cutting Repairing

Browse History

Key Features

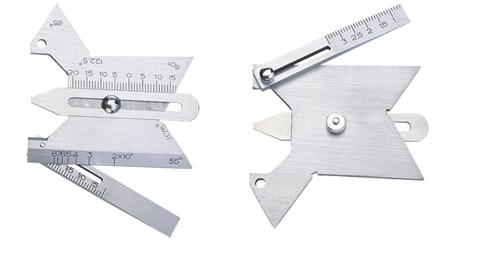

The product mainly consists of a main ruler, a slide gauge and an oblique gauge. It is a special measuring instrument used to measure the groove angle of the weldment and the width, height and gap of the weld. The ruler is applicable to products and parts with higher requirements on welding quality such as boilers, pressure vessels, and so on. Made of stainless steel, the product is reasonable in structure, good in appearance, convenient in use and wide in applicability, and is a necessary measuring tool for a welder.

The welding inspection ruler is listed in the enterprise standard issued by Electrotechncial Bureau of Machinery Industry Commission: the JB/DQ9004-87 Industrial Boiler Quality Rating Standard.

Technical Parameters

| Measuring Items | Range | echnicalParameters | Testing Tool |

| Height | 0-30mm | 0.2 |

0.2Vernier Caliper |

| Width | 0-12mm | WeldTwo-stage Flat Plate | |

| Welding Leg Width of Fillet Weld | 0-20mm | ||

| Mobile Groove Angle | 20°30°40°50°60°70°80° | ±2° | ±30′Special Angle Gauge |

| Check the Single-side Groove Angle | 117.5°-122.5° | ±30′ | ±10″Universal Angle Square |

| Groove Angle | 45°55°60°65° | ±30′ | ±10″Universal Angle Square |

| Gap Size | 0.5-.05mm | 0.1 | 0.2Vernier Caliper |

Instruction for use

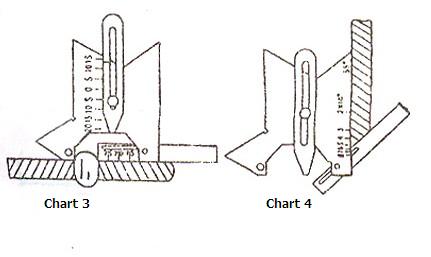

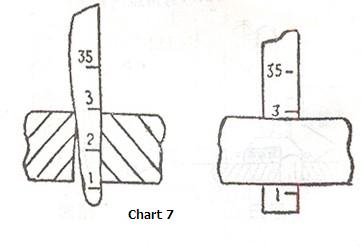

Use the slide gauge and the main ruler cooperatively to measure the height of the weld (Diagram 1) and the welding leg width of the fillet weld.

.jpg)

Use the oblique gauge and the main ruler cooperatively to measure the width of the weld and the angle of the weldment prior to assembly.

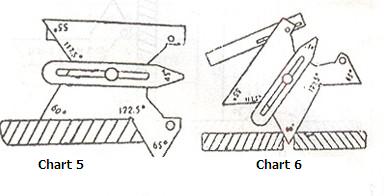

Use the 117.5°and 122.5°working angles of the main ruler to measure whether the groove of the weldment is up to standard or not prior to assembly.

Use the 45°working angle of the slide gauge and the 55°, 60°and 65°working angles of the main ruler to measure whether the groove of the weldment is up to standard or not after assembly.

Use the oblique gauge to measure unusual fit-up gaps.

1. Do not stack the welding inspection ruler together with other metal tools to deformation, and malfunction and blurred lines caused by friction.

2. Do not scrub the calibration with amyl acetate.