Product Knowledge

Switch the system from welding mode to cleaning mode at upper right corner of the home page, then restart the system.

First of all, you should change the torch to be cleaning status as the below video:

1, Selection of the focusing lens & relative focal length

replace to be an suitable focusing lens for the torch head and choose the relative focal length in the "Laser cleaning system".

2, Selection of Gas

If use Air, the air compressor should be at least 3-stage filtration which can get oil-free & water-free air.

The air pressure should be ≥ 0.3MPA.

The air flow should be ≥ 20L/min

Or you can also use other inert gas.

3, Technology Setting

Scanning frequency: swing speed of motor, ranging from 10 Hz to 10-100Hz, 80Hz is recommended.

Scanning width: the scanning width of the light spot depends on the lens specifications used by your model and is selected in the system settings.

Peak power: generally, it defaults to the maximum power of the laser.

Duty cycle: 100% by default

Pulse frequency: 2000 by default.

After setting the parameters, import and return, and you can see this process on the left side of the home page.

3, Confirm the Focus

By scanning back and forth for a long distance, the focus is when the sound is the loudest and the spark is the biggest. At this time, cleaning should be carried out according to this distance, and the energy is the strongest.

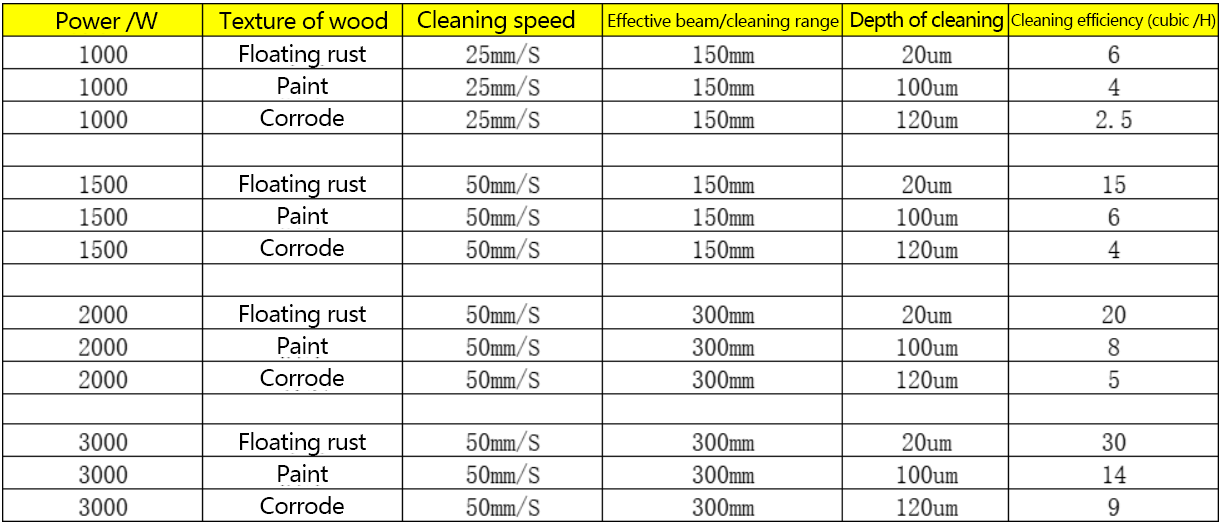

According to the use of focusing, the following is a reference.

F150 focusing (generally, the distance from the gun head to the plate is about 10-15cm, and the energy is the strongest).

F400 focusing (generally, the distance from the gun head to the plate is about 35-40 cm, and the energy is the strongest).

F800 focusing (generally, the distance from the gun head to the plate is about 75-85cm, and the energy is the strongest).

Note: When do cleaning, please keep the distance between the gun head and the plate stable, and the hand moving is also should be stable.