Product Knowledge

Switch the system from welding mode to cutting mode at upper right corner of the home page, then restart the system.

Cutting thickness: 3MM or less is suggested.

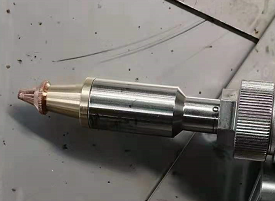

1, Selection of the Copper nozzles

Select the cutting nozzles and install the cutting nozzle to the laser head.

2, Selection of Gas

Using Nitrogen gas ( pressure ≥ 0.6MPA) can get a better cutting surface, the cutting surface is white. .

For thicker plate cutting, you can choose the Oxygen or Air to cut, the cutting surface will be a little black.

The Argon gas is not recommended , as it will cause poor cutting effect.

3, Technology Setting

● Scanning speed: Ignore this parameter, and you can do it at will.

● Scan width: 0

The cutting spot has no width. Therefore, the scanning width must be set to 0, that is, the red light is just a point.

● Peak power: the reference value suggests full power cutting, For example, if your power source is 1500W, then you can set 1500W.

● Duty cycle: reference value 100

● Pulse frequency: reference 1000

After setting the parameters, import and return, and you can see this process on the left side of the home page.

4, Adjust the focus

It is recommended to use negative focus, as negative focus will be less slag.

You can take a look at "Adjust the focus (Welding) " for reference.

5, Adjust the red light deviation to be center

Make sure that the red light completely comes out from the center of the copper nozzle, otherwise it may burn the copper nozzle.

You can take a look at "Adjust the red light deviation to be center (Welding) " for reference.