> Product Knowledge > Laser Welding > Difference between Continuous-Wave Laser and Pulsed Laser Product Knowledge

Laser cleaning – using a focused laser beam to rapidly vaporize or strip the contaminants on the material surface. Compare with all kinds of traditional physical or chemical cleaning methods, laser cleaning has the features of no contact, no consumable, no pollution, high precision, no damage or small damage, etc. It is an ideal choice for the new generation of industrial cleaning technology.

Further more, fiber laser with high reliability, stability and flexibility, has become the best choice of laser cleaning beam source. As the two major types of fiber laser, CW laser and pulsed fiber laser occupy the market of macro material processing and precise material processing respectively. For the emerging laser cleaning applications, there are questions about whether continuous laser or pulsed laser should be used. Here we compare the laser cleaning applications of continuous and pulse lasers, and analyze their respective characteristics and applicable application scenarios. Hope this article provides useful reference for you when choosing the corresponding laser cleaning technology.

CW Fiber Laser v.s Pulsed Fiber Laser on Cleaning

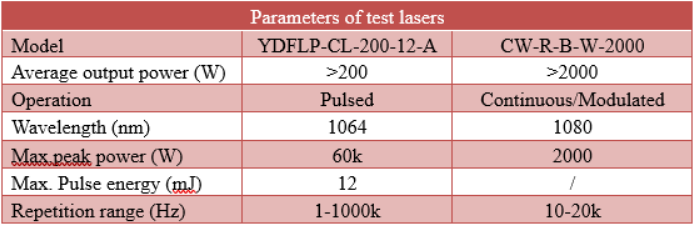

Below are the two models of JPT lasers used in this article.

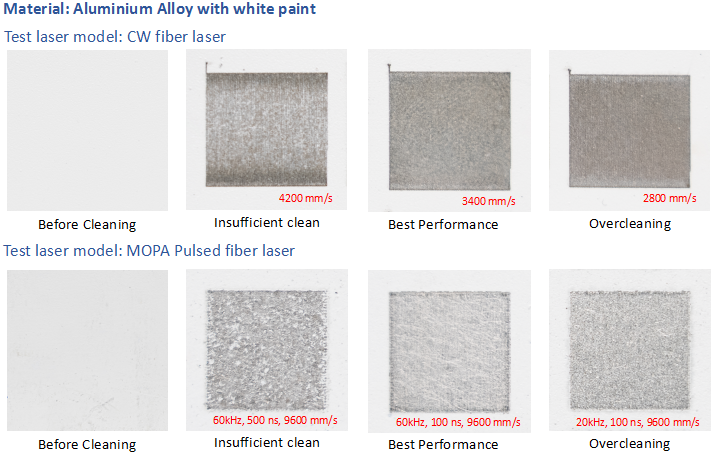

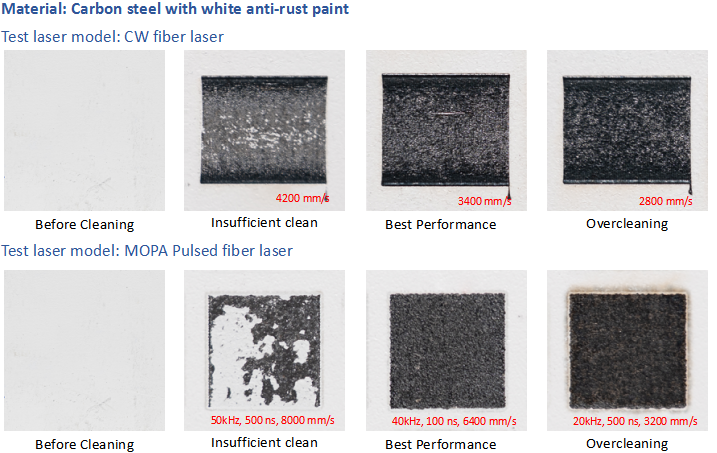

We use two models of lasers to clean different kinds of materials, one is aluminium alloy with white paint (around 20 um), and another is carbon steel with white paint (around 40 um).The cleaning performance is achieved by adjusting the pulse width (100ns, 200ns, 500ns ), frequency (20-60kHz) and scanning speed (1500-9600 mm/s). Figures below show the cleaning performance by test lasers in the above table.

Inappropriate parameter will result in unexpected cleaning performance. For pulsed fiber laser, laser with lower frequency is more likely to hurt the substrate during the cleaning process. And laser with narrow pulse width (around 100 ns) could clean the paint more easily. It’s essential to balance the heat between cleaning the paint and melting the substrate (heat effect). Fiber pulsed laser with MOPA structure brings the advantage of precise heat control, which is a critical point during the cleaning process.

For CW fiber laser, the slower the scanning speed is, the greater the hurt on the substrate will be. However, when the speed is higher than the threshold, quicker speed will cause insufficient cleaning. Thus when using the CW fiber lasers to do laser cleaning, it’s critical to choose the right scanning speed.

For the following article, details will be shown about difference between the CW fiber lasers and pulsed fiber lasers, from three main aspects: cleaning performance, cleaning efficiency and roughness after clean process.

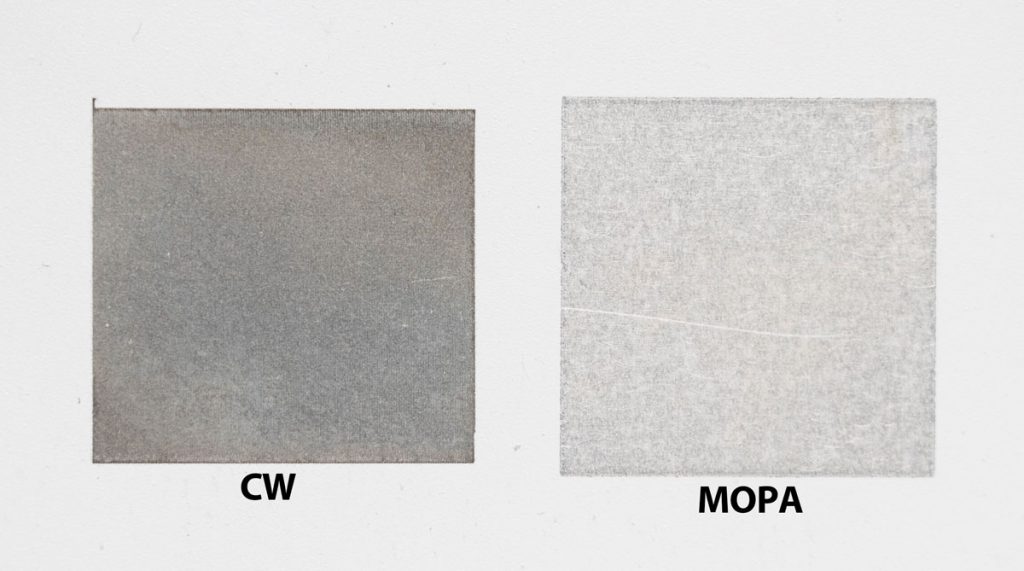

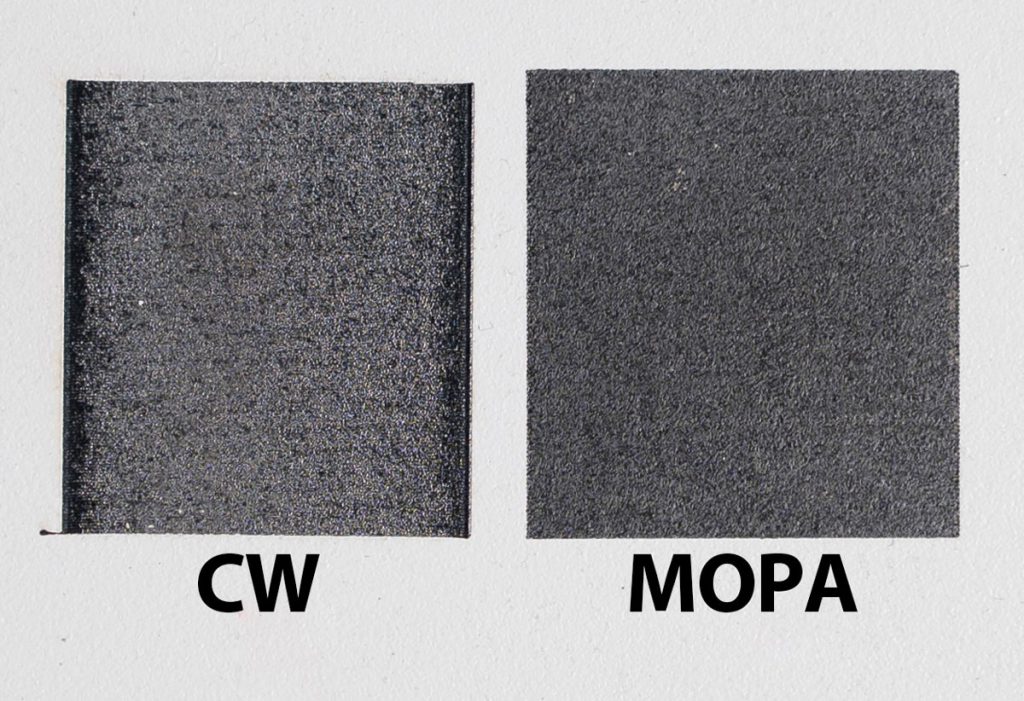

Intuitively, the materials are darker after cleaned by CW fiber laser, compared with MOPA pulsed fiber laser. Improper heat will result in the substrate mental melting during cleaning process, which is not acceptable especially in module cleaning industry.

Fig.2 (b) Cleaning performance comparison on carbon steel by CW (left) and MOPA pulsed fiber laser (right)

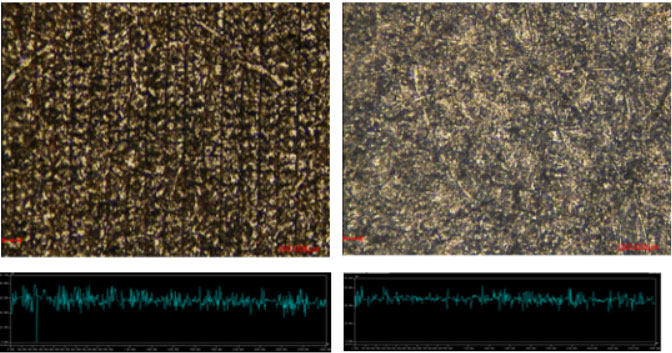

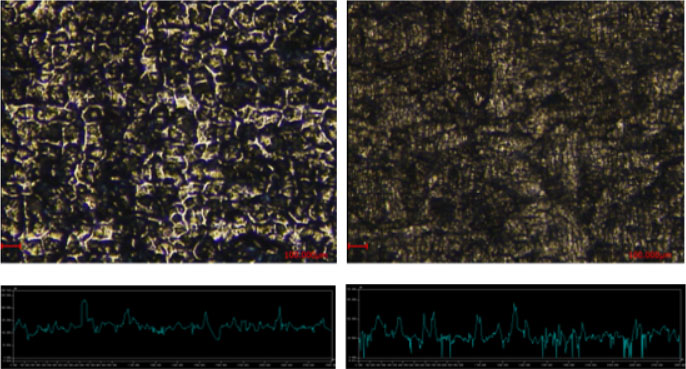

Under the microscope, the different microscopic surface of the substrate after cleaning could be easily shown. The mental on the substrate also melts during the CW fiber laser cleaning process, even though the paint is removed. However, for cleaning by MOPA pulsed fiber laser, the hurt on the substrate is small and the surface is more smooth.

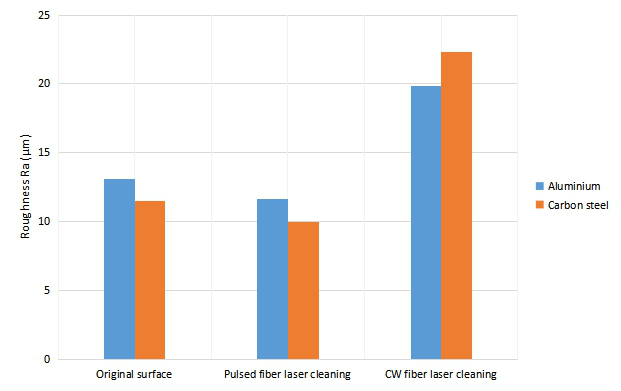

Further more, Figure 4 shows the roughness Ra for the surface by CW and MOPA pulsed fiber lasers. The hurt brought by MOPA fiber laser cleaning is very small, and the roughness value is close or even lower than the original surface (laser cleaned some dust on original surface too). While cleaned by CW lasers, the roughness value will be 1.5 times more than original surface.

Besides, another advantage brought by the MOPA fiber laser is high cleaning efficiency. When cleaning the dust on the Aluminium alloy, the cleaning efficiency of MOPA pulse fiber laser is 2.77 m²/h, which is 7.7 times of cleaning efficiency by CW fiber laser (0.36 m²/h). When cleaning the dust on the carbon steel, the cleaning efficiency of MOPA pulse fiber laser is 1.06 m²/h, which is 3.5 times of cleaning efficiency by CW fiber laser (0.3 m²/h)

Fig.4 Comparison for the roughness of the surface after CW and MOPA pulsed fiber laser cleaning

Conclusion

The dust could be remove both by MOPA pulsed fiber laser and CW fiber laser. Under same average output power, the cleaning efficiency of MOPA pulsed fiber laser is far more quicker than the efficiency of CW fiber lasers. In the meantime, precise heat control between cleaning and melting promise the good cleaning performance, without hurting the substrate.

However, the cost for CW fiber laser is lower, which compensates the disadvantage of the cleaning efficiency by increasing the average output power. But it will bring in worse heat effect, which will hurt the substrate.

Thus different cleaning application will request different laser model.For precise cleaning, such as mold cleaning, it’ll be better to choose MOPA pulsed fiber laser. For some large steel structures, pipes, etc., due to the large volume, fast heat dissipation and low requirement for substrate damage, continuous laser will be a good choice.